Mountain Productions’ Sandblasting Services

For over 40 years, MTN has gained extensive experience handling heavy duty metal maintenance. We know how important it is to keep your equipment in tip-top condition to extend its usable life for your business. We have constructed a state of the art SANDBLASTING workshop that serves the needs of large scale metal works .

Each member of our team has over 10 years of experience in advanced sandblasting using top of the line and fully compliant Clemco sandblasting equipment. We have serviced and refurbished thousands of metal structures with old paint and hard dirt particles into a reusable asset. Our services have already helped many companies bring their cost down and speed up the metal surface cleaning process.

Please call or message us to learn the MTN team that can maximize your costs and give your equipment a second life.

10 Years of Experience

Advanced Blasting Equipment

Serve Many Surface Finishing Purposes

Our Dry Blasting Booth

Dimensions: 15’ W x 32’ D x 8’ H

Blast Machine: Classic Clemco - Tough, Reliable, Top-Quality

Clemco Model: 2452 6 Cu Ft Hopper

Clemco Blast Cabinet: 3048INEX 300R&DF

Working Chamber: 48″ W x 28″ D x 28″ H

Viewing Area: 18-1/2″ W x 10-1/2″H

Capacity: The 6 cuft classic blast machine holds 6 cubic foot (approximately 600 lbs.) of abrasive blast media

Media: Black beauty blast media (standard). Other media available upon request

Classic Clemco - More than 50 years of reliable field service

Clemco Classic Blast Machine Startup

This large capacity blast machine, model 2452, provides professional sandblasting services to blasting contractors, shipyards, railcar re-man facilities and large scale industrial production.

Dimensions of Clemco 2452: 24’’(Dia.) x 52’’ (H)

Standard working pressure: 150psi

Capacity: 6 cu. ft.

Piping: 1’’ or 1-1/4"

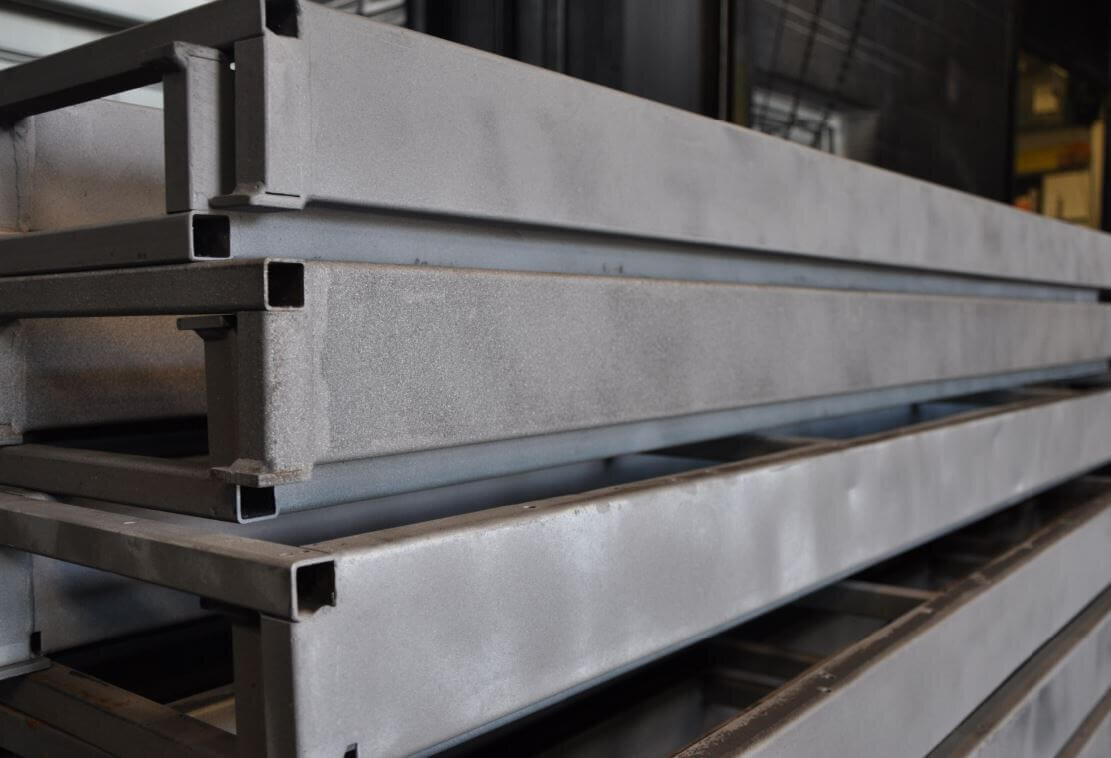

Previous Sandblasting Work:

Mountain Productions has been in the industry long enough to be able to complete any sandblasting jobs in an efficient and effortless manner.

Our services are backed up by a long standing company name. If you are looking for a service provider to get the job done right, then look no further. Our qualified crews has helped many companies to remove rust, paint etc from their structures, e.g.

Steel frame components

20’ sea container

Truss

I-beams

Other structural members

Gallery images show the differences between before and after treatment

Other Possible Work:

We never limit ourselves. No matter what sandblasting job whether it is for your home or business, you can count on our professionalism to offer you a great service at a competitive price. These are only some of the examples:

Steel components

Frame restorations (Blast and Paint)

Trailer Restoration

Heavy Equipment

Wrought Iron

Storage Containers

Storage Tanks

Dumpsters

More About Sandblasting

What is Sandblasting?

Sandblasting, also known as abrasive blasting, is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface or remove surface contaminants. Like rubbing sandpaper against a surface, sand paper contain many sand particles that remove some of the top-layer material to create a smoother texture.

The reason why it’s called “sandblasting” because it blasts the surface with particles of sand. As the rough and gritty sand particles strike the surface, they create a smoother and more even texture thanks to these properties.

How does Sandblasting work?

Our sandblasting specialists first pour the sand into the sandblasting machine which has a chamber on top in which the sand is poured. The machine is then connected to a conventional air compressor that propels the sand out through a nozzle. The sand that is in pressure is then “blasted” across the surface to create a smoother surface due to its abrasive properties. Our specialists have sandblasted different media for many purposes such as cleaning and smoothing. Check out our work and sandblasting equipment below